TL;DR: Integrating new tech into car repair services requires a tear down for estimate process, where technicians meticulously disassemble vehicles part by part to assess condition, identify repairs, and plan resource allocation. This method ensures accurate cost estimates, enhances quality through advanced technologies like paint equipment, improves efficiency with digital tools, and enables inventory management & recycling, ultimately providing competitive pricing and customer satisfaction in the auto collision repair industry.

In today’s competitive market, understanding the art of ‘tear down for estimate’ is a game-changer. This strategic approach involves disassembling products or systems to assess their components and value. By employing this method, businesses gain invaluable insights for accurate cost estimation and technology integration.

The article explores how this process benefits organizations by enabling them to make informed decisions, streamline operations, and achieve significant cost savings through meticulous planning.

- Understanding the Tear Down Process for Accurate Estimation

- Benefits of Early Technology Integration: A Competitive Advantage

- Streamlining Operations and Cost Savings through Comprehensive Planning

Understanding the Tear Down Process for Accurate Estimation

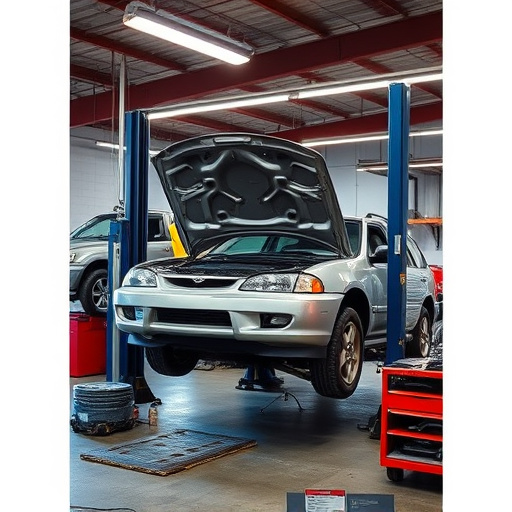

Understanding the tear down process is crucial for accurately estimating costs when integrating new technology into car repair services or auto body painting. It involves meticulously disassembling a vehicle, component by component, to assess its condition and identify potential repairs or replacements needed. This detailed analysis is key in determining not just the scope of work but also the resources and time required to complete specific tasks, such as fixing a vehicle dent repair or carrying out auto body painting.

By breaking down each part, professionals can better match technologies that enhance efficiency and precision in these tasks. For instance, advanced paint technology requires an accurate understanding of the existing surface condition, which is only possible through a thorough tear down. This ensures that any new equipment, like sanders or spray guns, are appropriately specified to deliver optimal results, enhancing the overall quality of car repair services and auto body painting.

Benefits of Early Technology Integration: A Competitive Advantage

Early technology integration offers a significant competitive edge in today’s fast-paced automotive industry. By tearing down vehicles for estimate purposes and incorporating advanced digital tools, auto collision repair shops can streamline their operations and gain a strategic advantage over competitors. This approach allows for more precise and efficient damage assessments, enabling repair technicians to identify issues that might be overlooked during visual inspections alone.

Through technology integration, car scratch repair and vehicle repair services can enhance customer satisfaction by providing accurate, real-time estimates. Such transparency builds trust and encourages customers to choose these shops over others that rely on traditional methods. Moreover, digital tools facilitate effective communication between estimators and technicians, ensuring a seamless workflow and minimizing errors in auto collision repair processes.

Streamlining Operations and Cost Savings through Comprehensive Planning

In the context of tear down for estimate, a strategic approach to vehicle dismantling and reassembly can significantly streamline operations and yield substantial cost savings. This involves meticulous planning and a comprehensive understanding of the underlying technology and processes involved in auto body repair, bumper repair, and auto frame repair. By methodically breaking down vehicles into component parts, professionals can accurately assess the condition of each element, identify reusable or recyclable materials, and efficiently estimate labor and material costs for subsequent reconstruction.

This meticulous tear-down process enables efficient inventory management by categorizing parts based on their quality and reusability, further enhancing cost control measures. Moreover, it facilitates the integration of advanced technologies in auto body repair and bumper repair, ensuring precision and minimizing waste during reassembly. Such technology integration not only streamlines operations but also enhances the overall quality and durability of repairs, making it a crucial strategy for any automotive facility aiming to optimize its processes and maintain competitive pricing in the market.

By understanding and implementing a thorough tear-down process for accurate estimation, businesses can unlock significant benefits. Early technology integration provides a competitive edge by enhancing efficiency and enabling data-driven decisions. Streamlining operations through comprehensive planning not only reduces costs but also facilitates faster project delivery, ensuring success in today’s fast-paced market.