The "tear down for estimate" process in automotive repair involves meticulous disassembly and inspection to accurately plan labor and material for hidden damage repairs. Skilled technicians document components, calculate labor hours using historical data, and determine repair sequences, ensuring precise cost estimates and efficient scheduling for prompt, budget-conscious restoration. This systematic approach enhances operational efficiency, minimizes errors, and boosts customer satisfaction in a bustling automotive services environment.

In the construction industry, precise planning is key to project success. A vital step often overlooked but critical for efficient project management is the tear-down process for creating accurate estimates. This article explores how understanding and optimizing this initial phase can revolutionize labor scheduling. By breaking down tasks, we can better estimate time and resources needed, ensuring a well-coordinated workforce. We’ll delve into essential components of labor scheduling coordination, highlighting strategies to enhance overall project productivity.

- Understanding the Tear Down Process for Estimates

- Key Components in Labor Scheduling Coordination

- Optimizing Efficiency Through Comprehensive Planning

Understanding the Tear Down Process for Estimates

The tear down process for estimates is a meticulous procedure that forms the foundation for accurate labor and material planning in automotive repairs. It involves a thorough inspection and disassembly of the damaged vehicle to assess the extent of car damage repair needs. This step-by-step breakdown, or “tear down,” allows technicians to create precise estimates for both labor and parts, ensuring every aspect of the repair process is accounted for. By meticulously documenting each component’s condition, removal, and potential replacement requirements, this method enhances transparency and facilitates effective scheduling.

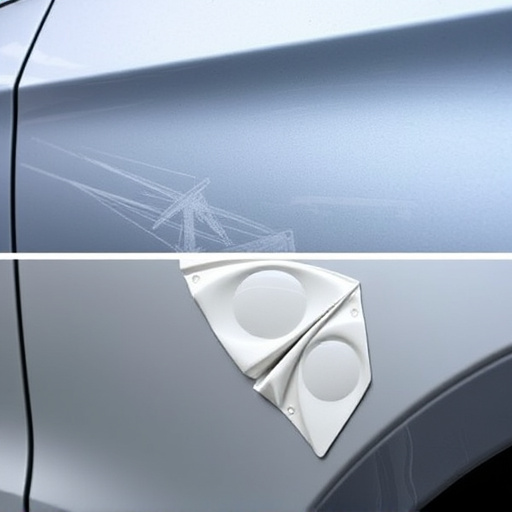

Understanding car body repair fundamentals is crucial here. The tear down reveals hidden damage, such as underlying panel dents or structural weaknesses, which might not be immediately apparent. This information is vital for scheduling as it dictates the sequence of repairs, including tasks like car dent repair, metal welding, and paintwork, ensuring a seamless restoration process.

Key Components in Labor Scheduling Coordination

In the realm of tear down for estimate and labor scheduling coordination, several key components come into play to ensure a seamless and efficient process. The initial step involves a thorough tear down of the vehicle, which means completely disassembling it to assess its condition and identify necessary repairs. This meticulous process is crucial in generating accurate estimates for both parts and labor, providing clients with transparent costs before any work commences.

During tear down, skilled technicians meticulously document every component, paying close attention to details that might impact repair complexity and time. Once the disassembly is complete, these professionals utilize specialized software or manual calculations to estimate the required labor hours based on historical data and their expertise. This step is vital for collision repair centers and even classic car restoration specialists to manage resources effectively and schedule labor accordingly, ensuring every project is completed promptly and within budget.

Optimizing Efficiency Through Comprehensive Planning

In the realm of auto body repair and vehicle collision repair, comprehensive planning is a game-changer. By implementing meticulous tear-down for estimate processes, repair shops can significantly enhance their operational efficiency. This involves a systematic disassembly of damaged components to accurately assess the scope of work required, ensuring every step is accounted for in the estimate. Such detailed planning minimizes errors and unexpected costs, streamlining the entire process from initial assessment to final restoration.

This strategic approach optimizes labor scheduling by aligning available resources with the repair schedule. It allows for more accurate time frames, better workforce allocation, and reduced downtime. In a bustling automotive repair services environment where every minute counts, this meticulous planning ensures vehicles are back on the road promptly, enhancing customer satisfaction and fostering a positive reputation for quality service.

By streamlining the tear-down process and implementing efficient labor scheduling coordination, construction projects can significantly enhance their precision, reduce costs, and optimize timelines. Understanding the intricacies of this process and integrating comprehensive planning into project management are key strategies to ensure successful outcomes. Embracing these practices allows for accurate estimates and effective resource allocation, ultimately revolutionizing how we approach construction logistics in today’s competitive market.